Click here to download a PDF outlining this project.

Client: Moonshot

Location: Remote

Start Date: March 2022

Completion Date: March 2022

Resolute Engineering was tasked with designing two immersion fluid cooling process design system configurations. One 50 Megawatt and one 100 Megawatt mining facility.

Resolute Engineering was tasked with designing two immersion fluid cooling process design system configurations. One 50 Megawatt and one 100 Megawatt mining facility.

- Prepared CFD (Computational Fluid Dynamics) Model using ANSYS Software and Process Modeling using Schlumberger Symmetry Software.

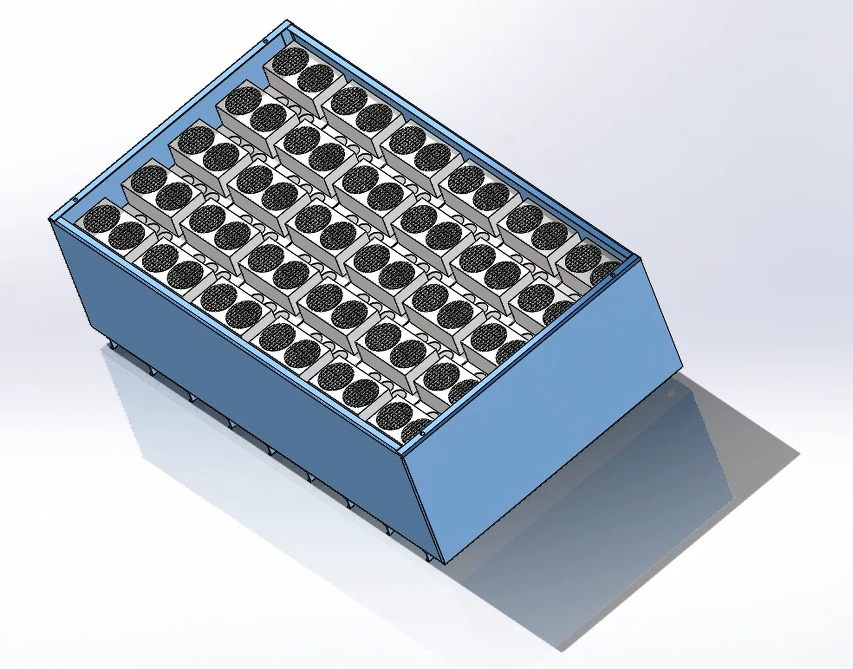

- The base configuration has one or more bath for the miner cooling (30 miners per bath) using a heat transfer fluid, a pump, a dry-cooler to cool the fluid, and a filter.

- ICE 1000 was used in the calculations for the heat transfer fluid.

- Develop distribution header and redo manifolds to optimize mining rig capacity and minimize heat.

- The following three options are available when it is not possible to cool the fluid down to 95°F using ambient air:

- 1. Operate fewer miners so the exit bath temperature is kept below 135°F.

- 2. Enhanced design which includes a refrigeration unit to chill the fluid coming from the air-cooler.

- 3. Overdesign the system such that a entering bath fluid temperature of 115°F is acceptable.

Types of Projects

Types of Projects